SCALABLE

ECONOMIC

RECYCLING.

CLEANER. SMARTER.

VIRIDIS.

We transform used batteries into a resource for the future.

We treat various batteries from production scrap or end of life. After material specific pretreatment, all input material passes our HydroPulse™ process to separate the components and make them available as valuable resource. No matter where in the battery life cycle you are or what end-of-life product you have, we are your recycling partner.

Innovative recycling technology

We revolutionize battery recycling, achieving a high degree of material separation with our HydroPulse™ technology.

Green CO2 – reduced process

We cut back on energy use, drastically reducing CO2 emissions.

Energy efficient battery recycling

We recover critical materials with high efficiency by avoiding metallurgical processing .

Our innovative process

Processing of diverse battery chemistries and formats

We process end-of-life batteries and production scrap, including NMC, NCA and LFP cells of all geometries and sizes. After delivery, the batteries are carefully sorted, discharged and dismantled. The material is then prepared for the punching process, which marks the next step in our recycling procedure.

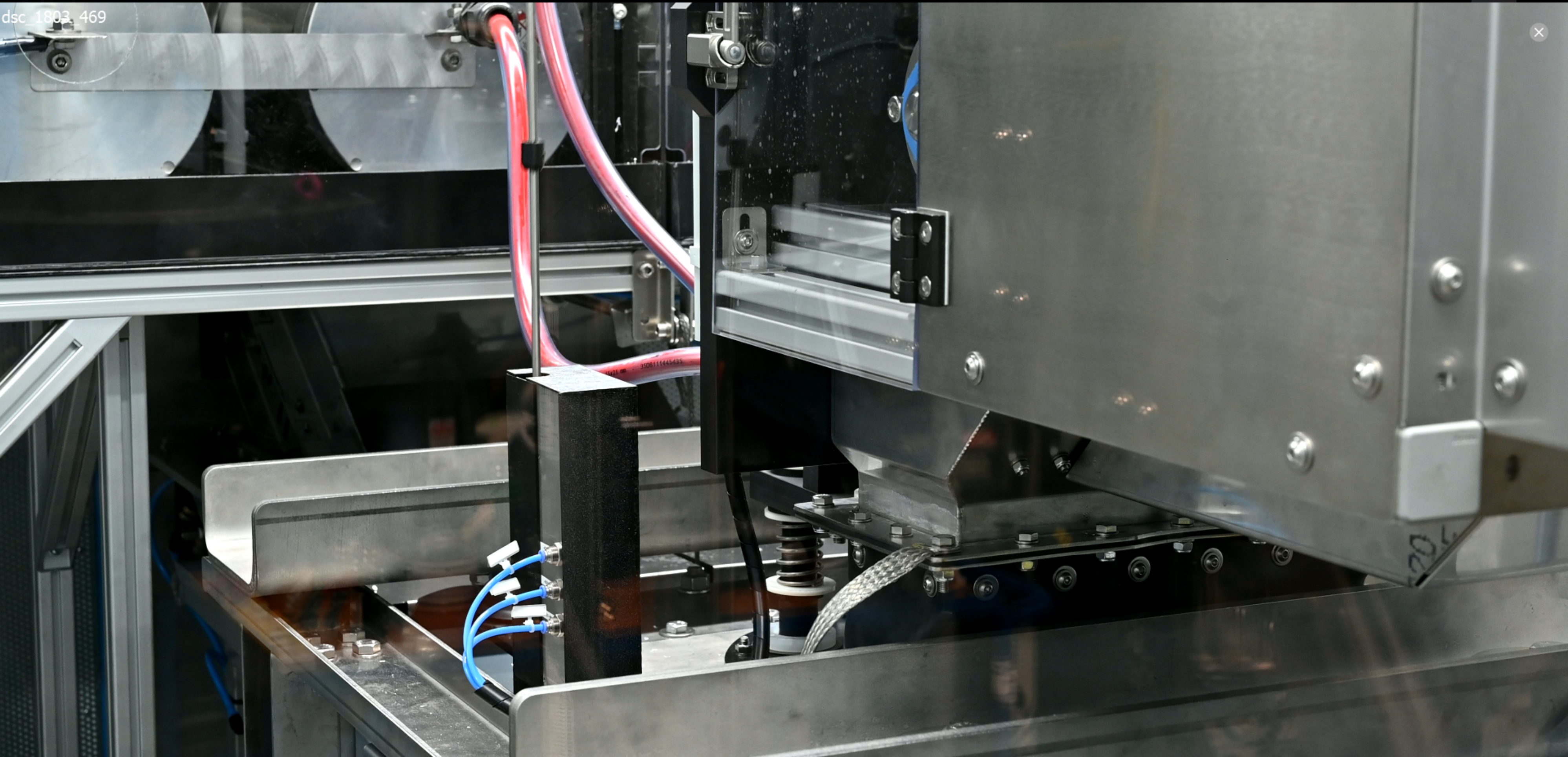

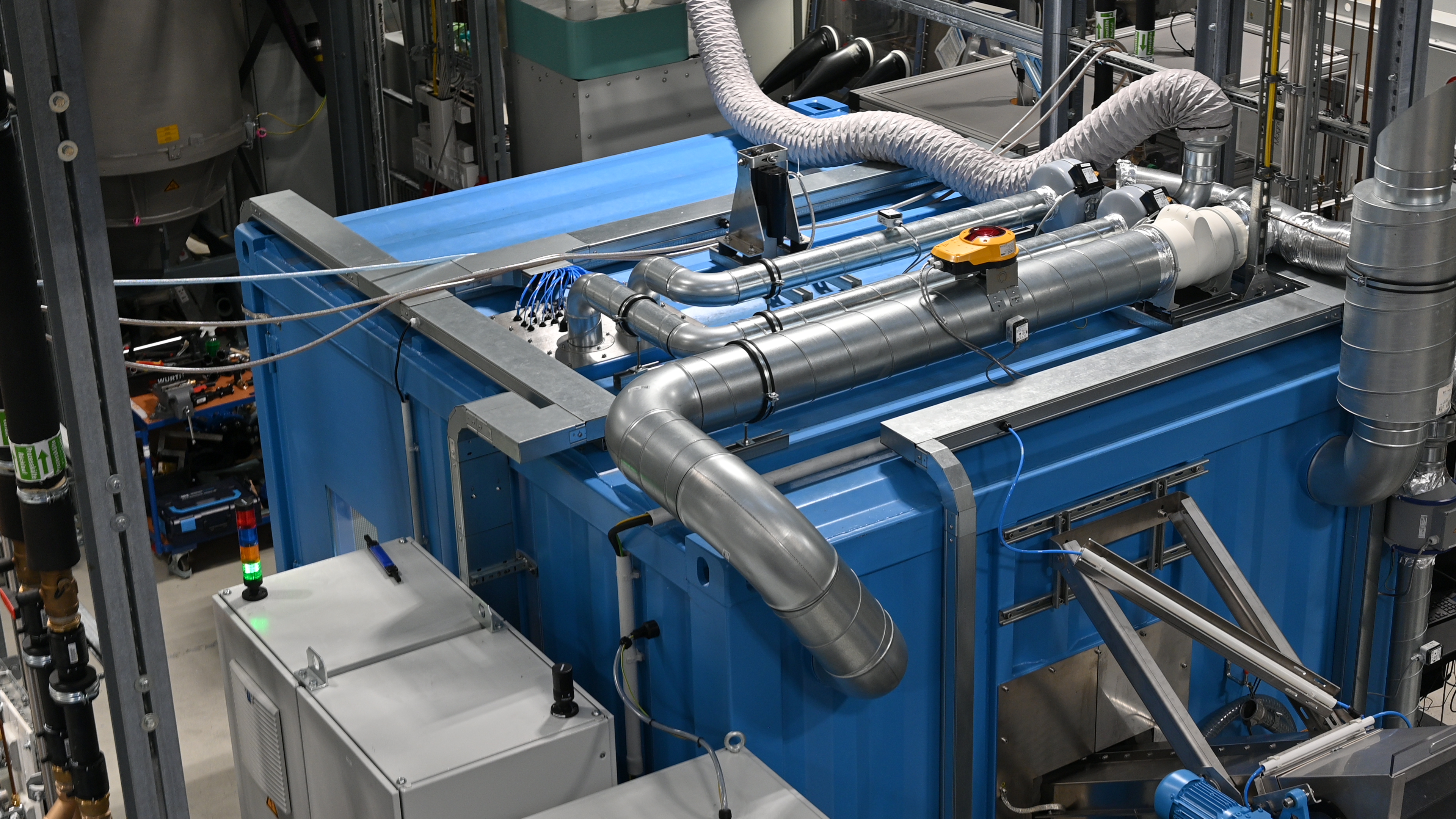

HydroPulse™ Technology

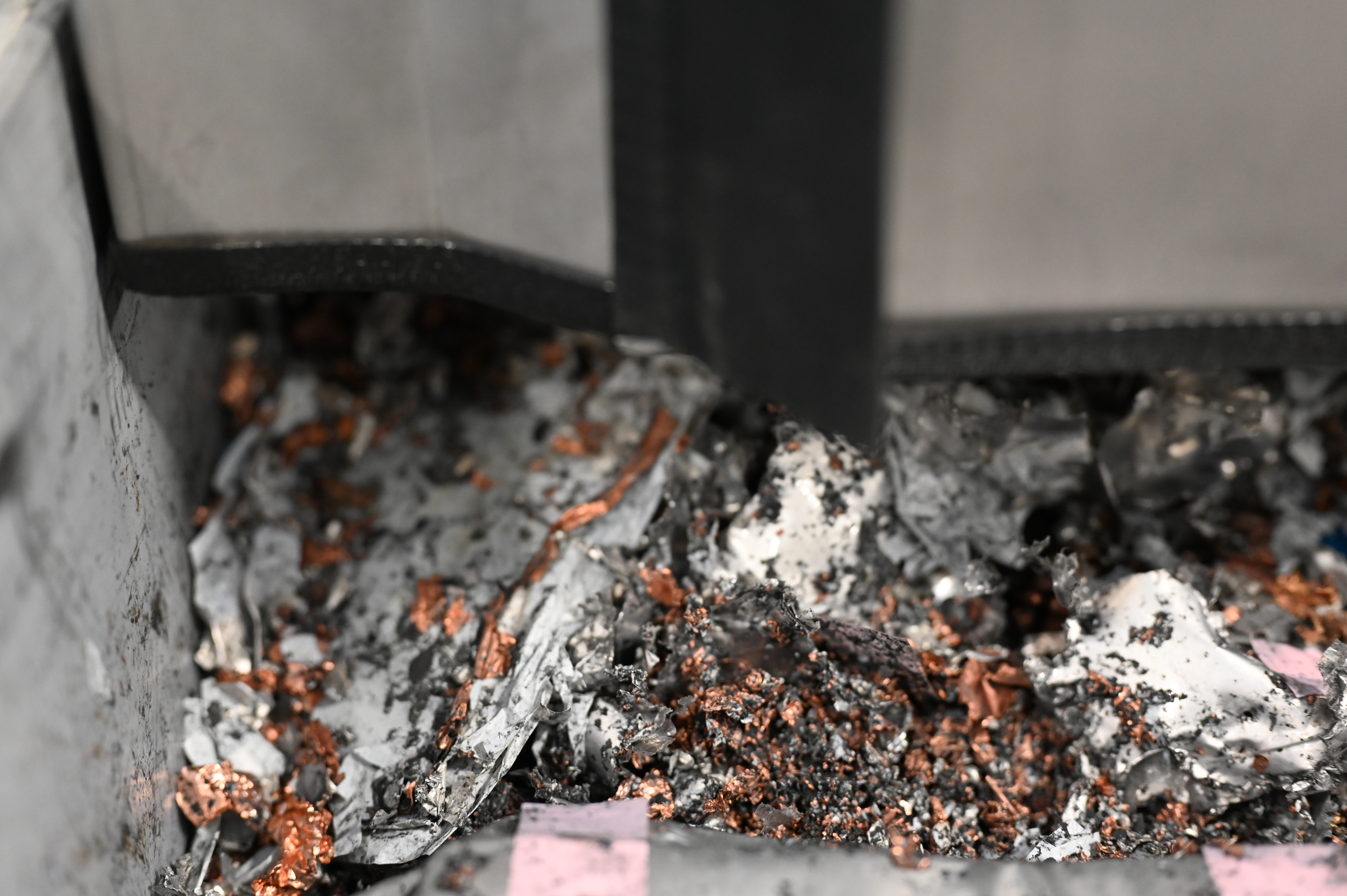

After mechanical preparation, the battery cells are treated in our HydroPulse™ process. This method uses a mild mechanical treatment by aqueous shockwaves that separates different materials. With our complex multistage sorting, we receive high purity material fractions.

Post processing

Using advanced washing, centrifugation and sieving techniques, we can recover high-purity active materials giving them a second life in next-generation batteries and driving true circular innovation.